2025/03/21Views(21734)Reviews(0)

一、Target Audience

Operators, Warehouse Staff

二、Feature Introduction

SellerSpace - Inventory Analysis Feature. Inventory management is indispensable for successfully operating an Amazon business. With it, you no longer need to worry about losing sales due to stockouts or paying expensive storage fees for overstock. It helps you view product inventory status anytime, anywhere, effectively maintain inventory turnover, accelerate inventory flow, and reduce capital tied up in inventory.

Through the Inventory Analysis feature, you can view the following metrics:

Total Inventory, Sellable Quantity, Inbound Quantity, Reserved Quantity, Under Investigation Quantity, Unsellable Quantity, Listing Price, Sale Price, Estimated Inventory Value, Estimated Product Cost, Sales in the Last 3/7/14/30 Days, Daily Sales, Days of Supply, Inventory Status, Local Available, To Be Delivered, Purchase Plan, Lead Time, Recommended Purchase Quantity, Recommended FBA Shipment Quantity, etc.

三、Use Cases

1. Inventory Basic Overview: View product inventory quantities for any store or all stores, including total quantity, sellable quantity, inbound quantity, reserved quantity, under investigation quantity, unsellable quantity, and other data.

2. Replenishment Recommendations for Best-Selling Products: Provide recommended purchase quantities and recommended FBA shipment quantities for best-selling products based on specific data logic.

Replenishment Data Logic

Recommended Purchase Quantity Calculation Formula:

Recommended Purchase Quantity = Lead Time * Daily Sales - (Sellable Quantity + Inbound Quantity + Under Investigation Quantity + Transfer Reserved + Processing Reserved + Local Available + To Be Delivered + Purchase Plan)

Recommended FBA Shipment Quantity:

Recommended Shipment Quantity = (First Leg Transportation Time + Safety Stock Days) * Daily Sales - (Sellable Quantity + Inbound Quantity + Under Investigation Quantity + Transfer Reserved + Processing Reserved)

3. Identify Slow-Moving Inventory: Evaluate your product inventory status based on "Days of Supply" to help you maintain inventory turnover and reduce capital tied up in inventory.

四、Data Synchronization Frequency

Inventory data synchronization frequency: Synchronized approximately every 1-2 hours.

五、Operation Guide

1. Filter Query Conditions

SellerSpace provides multi-dimensional filtering conditions. You can analyze your store's product inventory status from different marketplaces, different product statuses, different inventory statuses, different brands, different grouping tags, different ERP product tags, and other dimensions.

1.1 Support Viewing Single Marketplace or Multiple Marketplaces

+

+

1.2 Support Viewing by Product Status

+

+

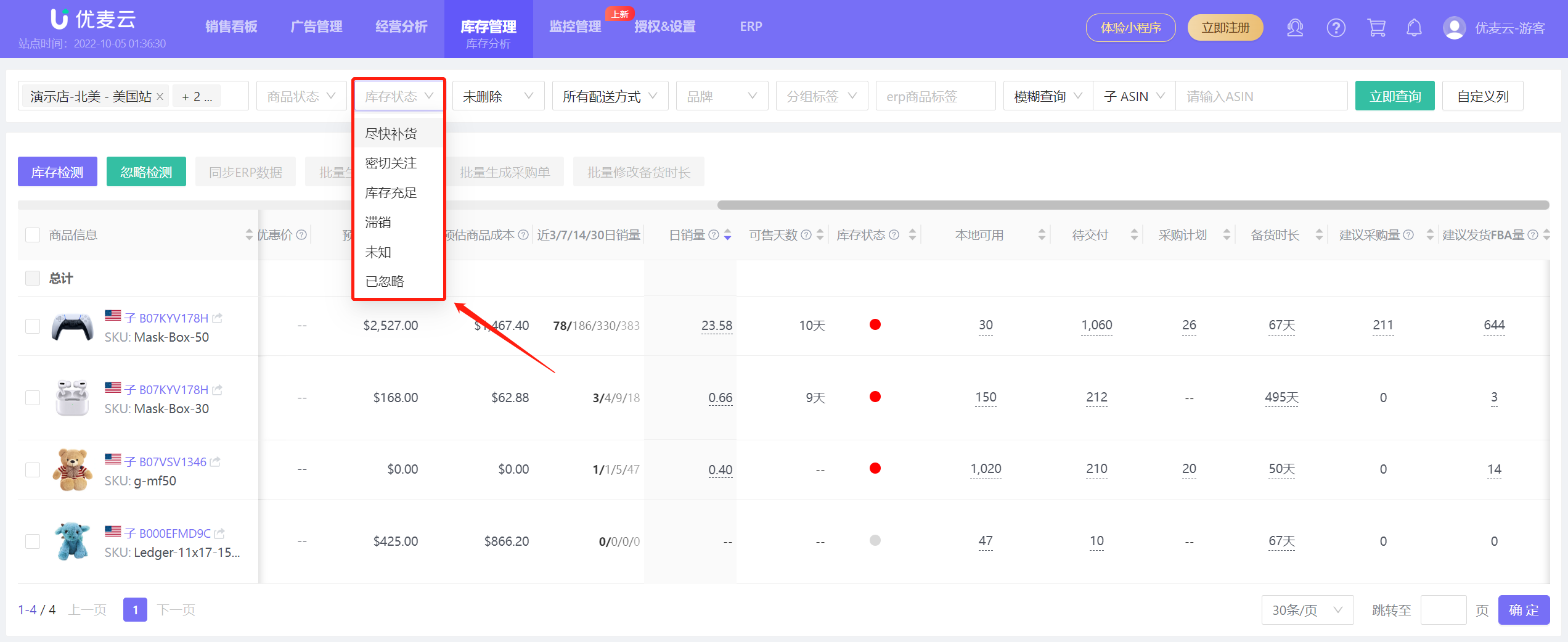

1.3 Support Viewing by Inventory Status

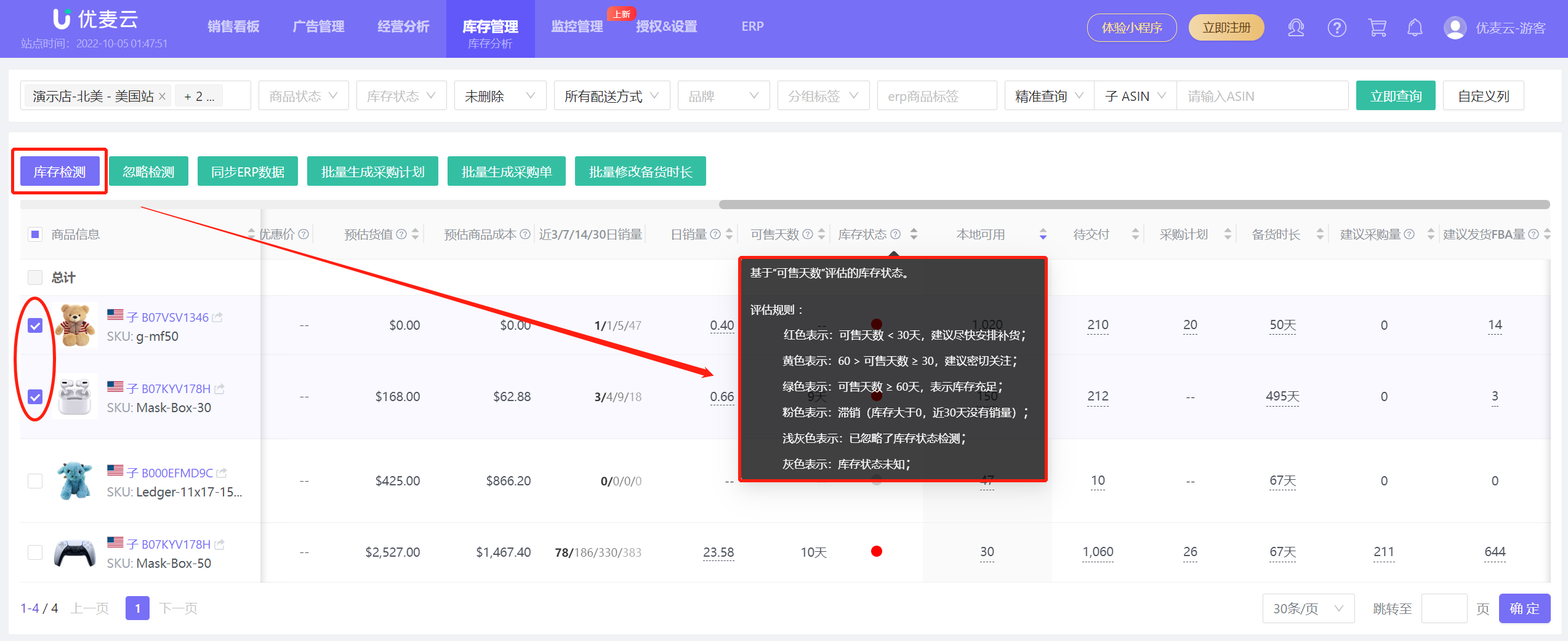

Inventory status evaluated based on "Days of Supply". Evaluation rules: Days of Supply < 30 days, replenishment is recommended as soon as possible; 60 > Days of Supply ≥ 30, close attention is recommended; Days of Supply ≥ 60 days, indicating sufficient inventory; Slow-moving (inventory greater than 0, no sales in the last 30 days); Ignored and Unknown inventory status.

+

+

1.4 Support Viewing Deleted and Non-Deleted Products

Products can be deleted in Product Cost. Deleted products are recorded by the system and can be filtered and viewed through "Deleted". (Deletion is only performed in the SellerSpace system and will not delete products in the Amazon backend. Data will no longer be synchronized after deletion.)

+

+

1.5 Support Viewing by Fulfillment Method

+

+

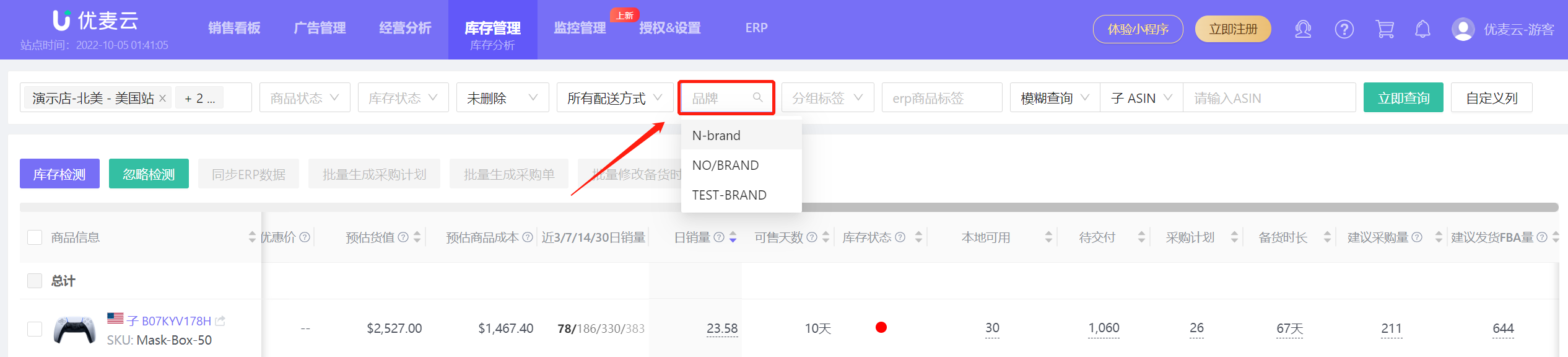

1.6 Support Viewing by Different Brands

+

+

1.7 Support Viewing by Different Grouping Tags

Grouping Tags: You can group products according to your habits in different dimensions to contextualize statistics. For example: brand, industry, characteristics, etc., to facilitate quick browsing and comparative analysis. Click the edit icon to set tags for the product. For products with tags already set, click the tag to update it.

+

+

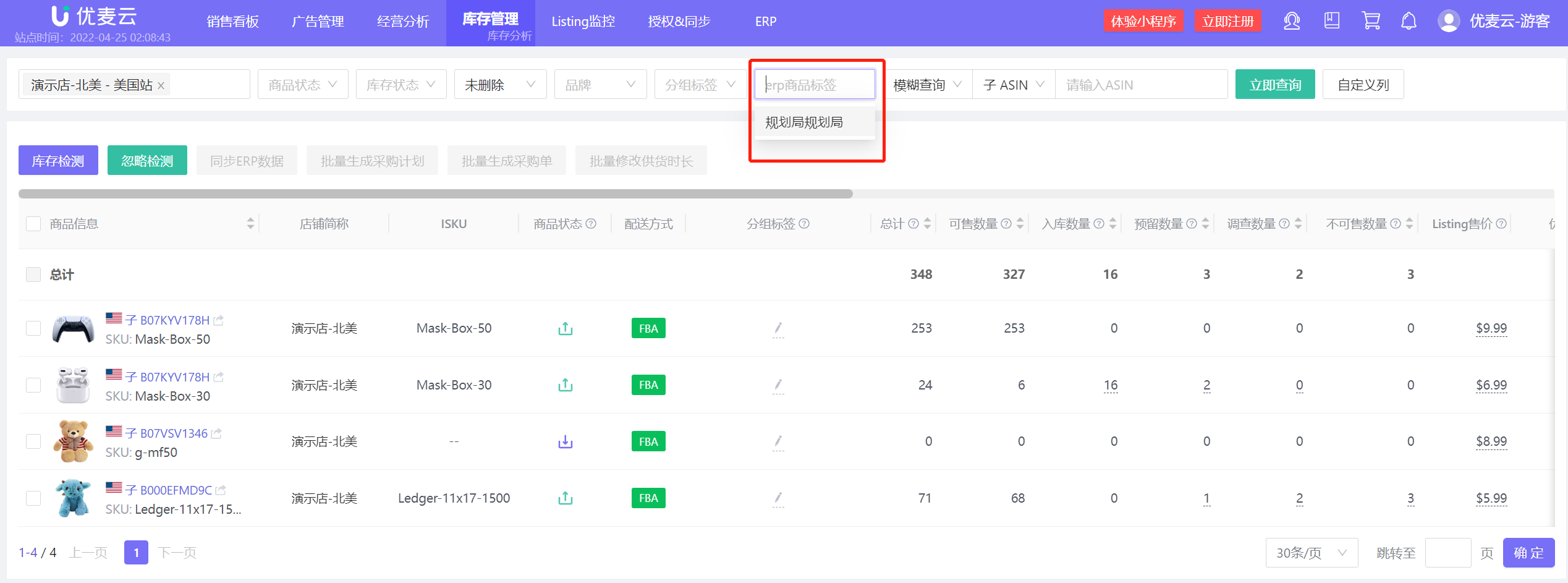

1.8 Support Viewing by Different ERP Tags

ERP tags are set based on the local ISKU dimension. You can group local products according to your habits in different dimensions to make management more convenient.

+

+

Differences between Grouping Tags and ERP Tags:

Grouping tags are marked based on the Amazon ASIN/SKU dimension, while ERP tags are marked based on the local ISKU dimension.

When a seller operates multiple stores or marketplaces for one product, one local ISKU may correspond to multiple Amazon SKUs.

1.9 Fuzzy Query and Exact Query

Fuzzy Query: Fuzzy matching is performed according to the conditions you enter. For example, if you use SKU fuzzy query: AM0001, all SKUs containing AM0001 will be displayed, such as product records like AM0001_S_M, AM0001_S_L, etc.;

Exact Query: Exact matching is performed according to the conditions you enter. Only product records that exactly match your search conditions will be displayed.

Supports filtering by SKU, Parent ASIN, and Child ASIN dimensions.

+

+

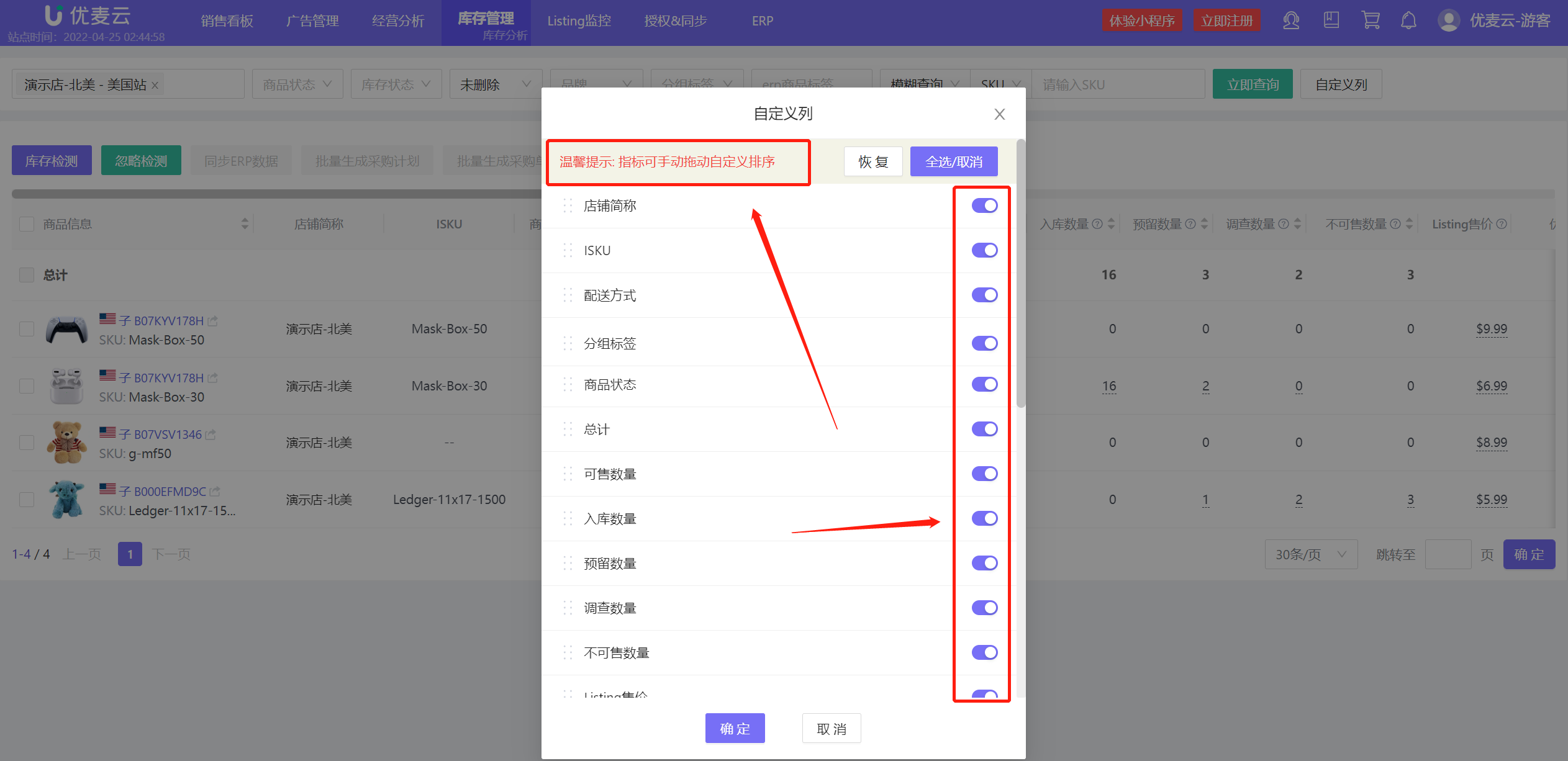

1.10 Customize Columns

+

+

Helps customers customize the display order of metrics and also turn off metrics they don't want to display by sliding the switch button, providing a more convenient data display for analysis (Friendly reminder: Metrics can be manually dragged to customize the sorting).

2. Using Inventory Analysis

2.1 Detect Inventory Status

Check the ASINs you need to judge, click "Inventory Detection" to update the inventory status of the product. If you do not need to judge the inventory status of this ASIN, you can click "Ignore Detection". After ignoring, this ASIN will not participate in the inventory status calculation rules.

+

+

+

+

+

+

+

+

Friendly Reminder:

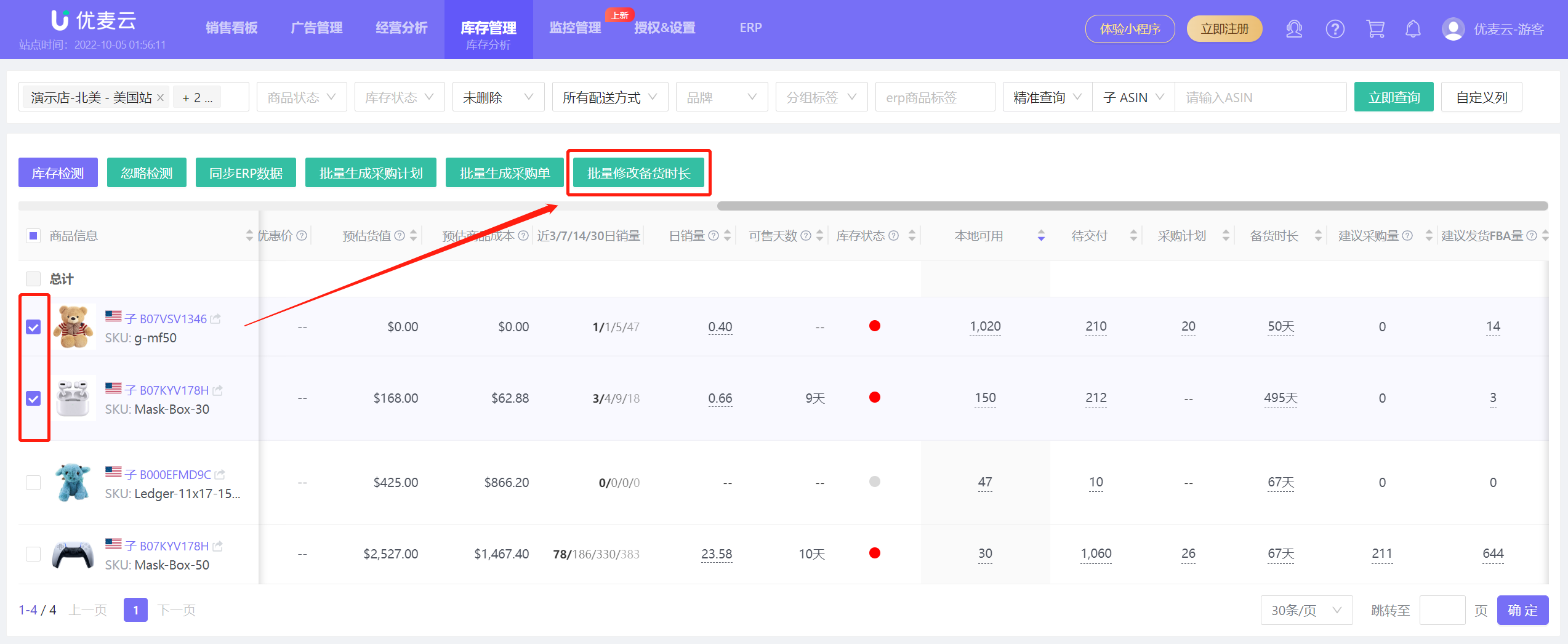

2.4 Modify Lead Time

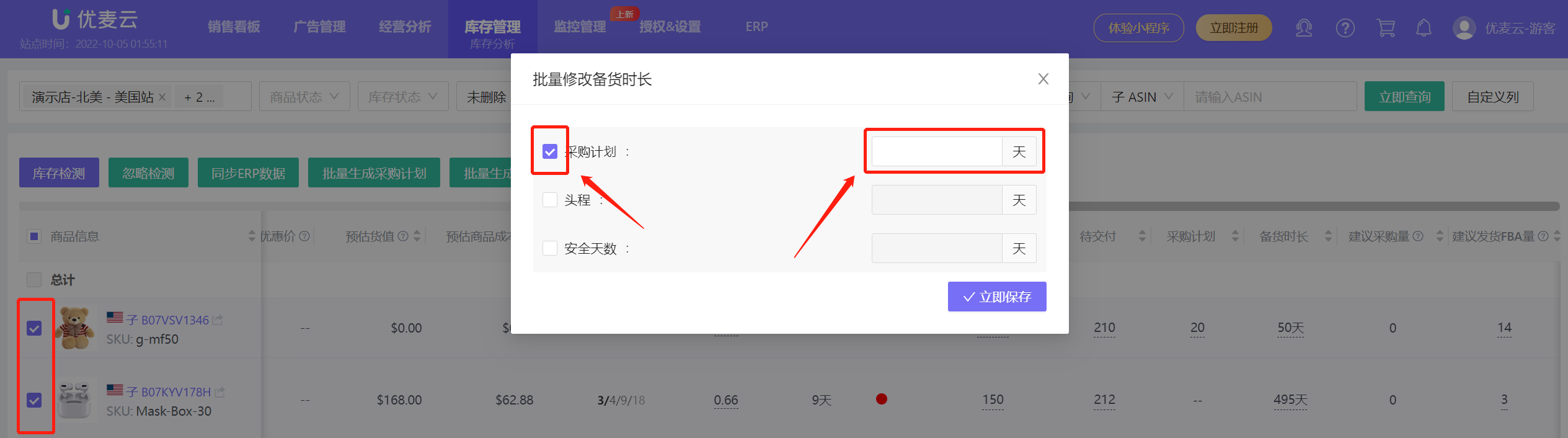

2.4.1 Bulk Modification

Select the SKUs for which you need to modify the lead time, and then click "Bulk Modify Lead Time". Check the selection box in front of the metric and modify the required Purchase Plan Days, First Leg Transportation Time, and Safety Stock Days according to your product situation.

+

+

+

+

Purchase Plan Days: Refers to the number of days required from creating a purchase plan to placing an order with the supplier;

First Leg Transportation Time: Refers to the number of days required from domestic warehouse/overseas warehouse to FBA warehouse/overseas warehouse;

Safety Stock Days: The number of days required to maintain continuous stock. Generally speaking, Safety Stock Days > Purchase Plan Days + First Leg Transportation Time + Purchase Days. If your first leg transportation time is 15 days, the purchase plan is 3 days, and the purchase days are 10 days, then the safety stock days here are 28 days. If you want to maintain continuous stock, then you need: Inventory Safety Stock Days > 28. Once you find that the Days of Supply is close to 28, you need to arrange production and shipment immediately.

2.4.2 Individual Modification

To modify the lead time of a single product, you can click the underlined number in the "Lead Time" column to modify and save.

+

+

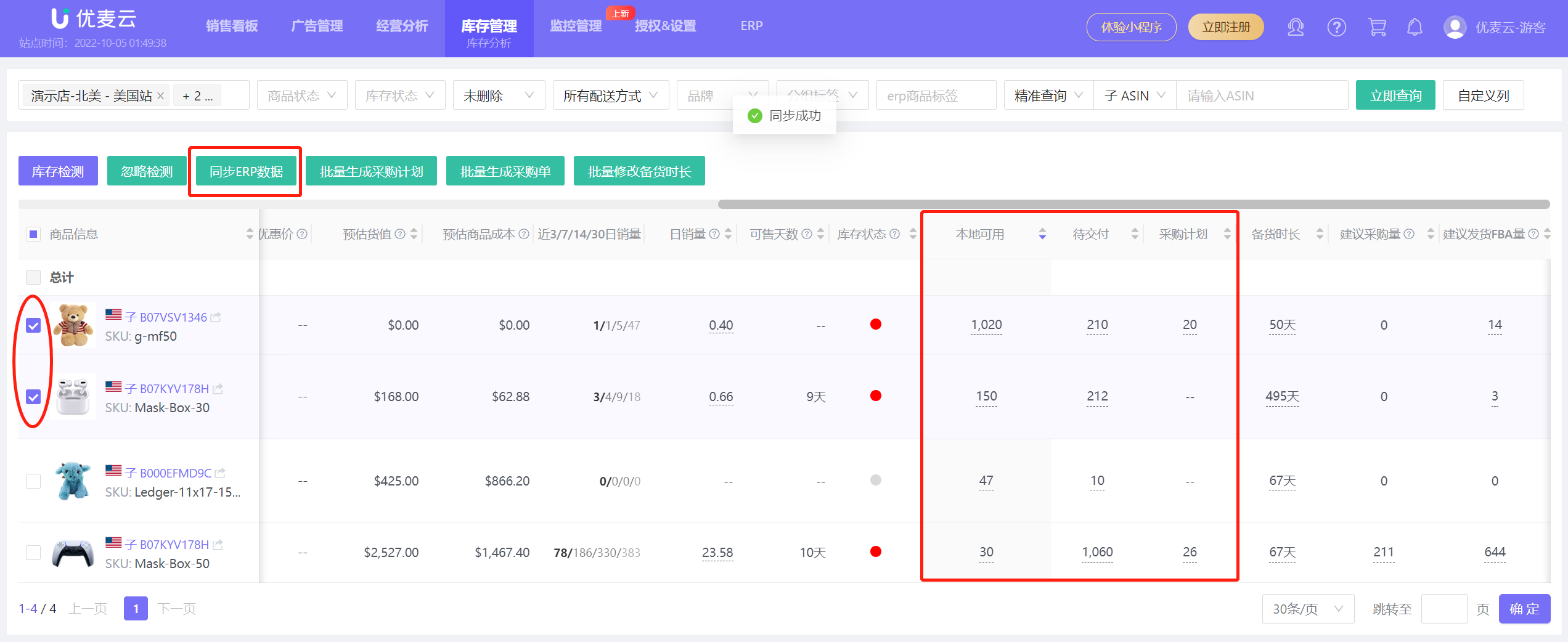

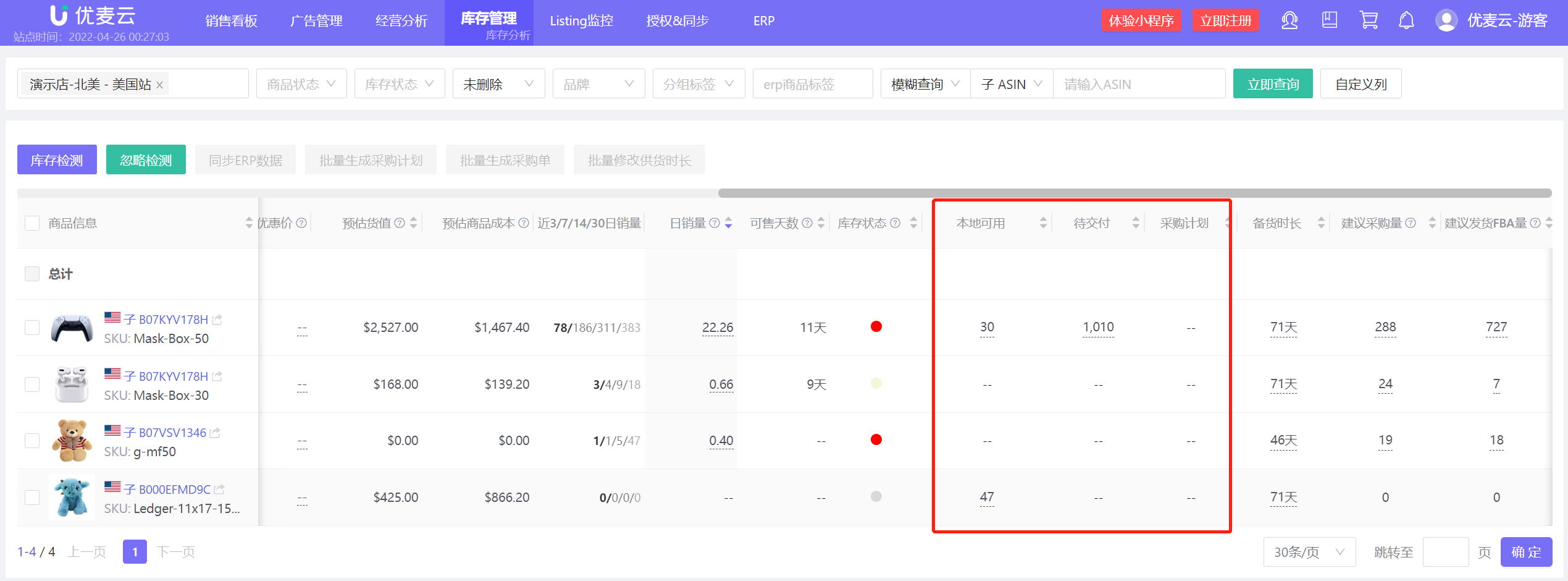

2.5 View Inventory Data

You can view total inventory, sellable quantity, inbound quantity, reserved quantity, under investigation quantity, and unsellable quantity.

+

+

Hover the mouse over the number to see the specific details. You can view the specific explanation of the field by clicking the question mark in the upper right corner of the field.

+

+

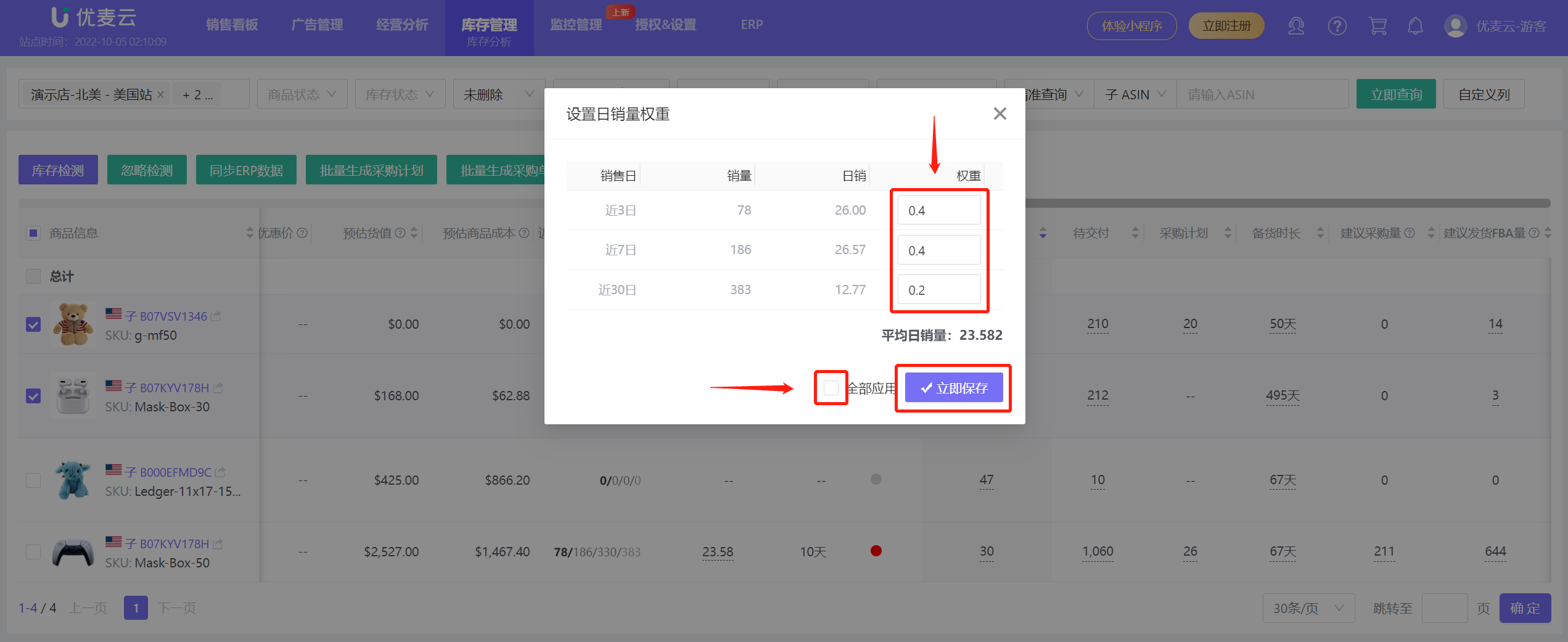

2.6 Customize Daily Sales

Daily sales data calculation rules: Sales in the last 3 days * Weight ratio of sales in the last 3 days + Sales in the last 7 days * Weight ratio of sales in the last 7 days + Sales in the last 14 days * Weight ratio of sales in the last 14 days + Sales in the last 30 days * Weight ratio of sales in the last 30 days;

Preset rules: Sales in the last 3 days * 40% + Sales in the last 7 days * 30% + Sales in the last 14 days * 20% + Sales in the last 30 days * 10%;

+

+

Click the underlined number below "Daily Sales" to set it. Can be applied to a single SKU or check "Apply to All" to apply to all products.

+

+

Friendly Reminder:

For existing customers, if you have customized the daily sales weight, you can only see and set the weights for 3/7/30 days, and cannot set the weight for 14 days.

For customers who have not customized or new customers or new products, you can set the weights for these 4 dimensions: 3/7/14/30 days. If customers who have customized need to set the 14-day weight, please contact technical support for processing.

The sum of weights range is 0-10. For example, if last month was the peak season, the weight set this month can be considered to be less than 1. If last month was the off-season and this month is the peak season, you can set the weight to be greater than 1.

+

+

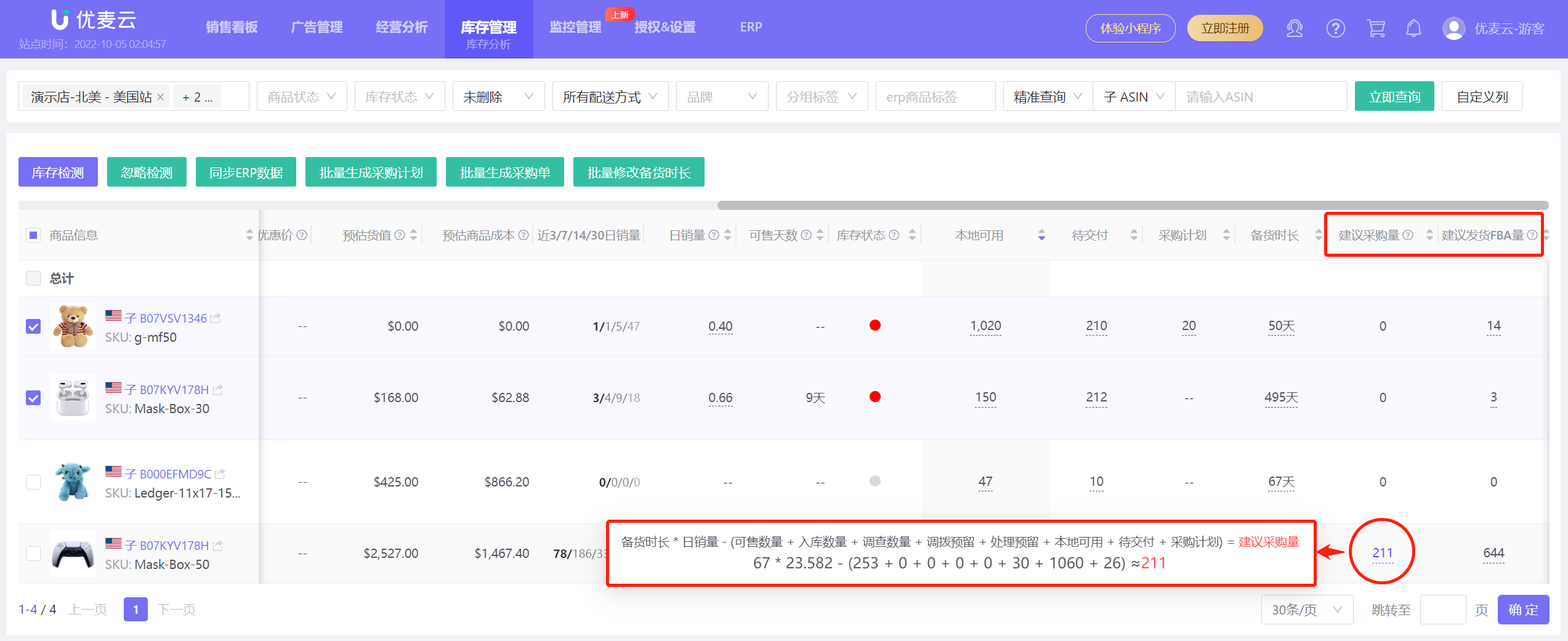

2.8 Recommended Replenishment

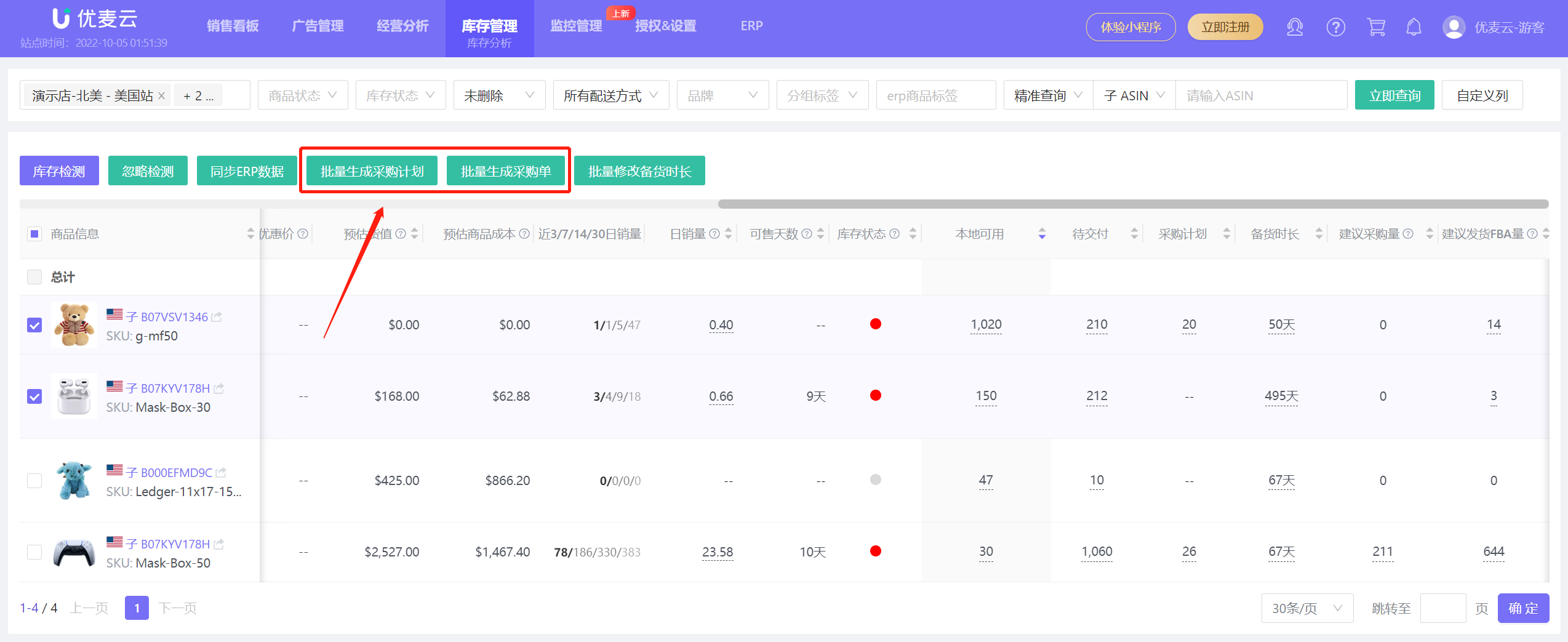

Recommended Purchase Quantity Calculation Formula:

Recommended Purchase Quantity = Lead Time * Daily Sales - (Sellable Quantity + Inbound Quantity + Under Investigation Quantity + Transfer Reserved + Processing Reserved + Local Available + To Be Delivered + Purchase Plan)

Recommended FBA Shipment Quantity:

Recommended Shipment Quantity = (First Leg Transportation Time + Safety Stock Days) * Daily Sales - (Sellable Quantity + Inbound Quantity + Under Investigation Quantity + Transfer Reserved + Processing Reserved)

+

+

If you want to modify the recommended purchase quantity and recommended FBA shipment quantity, you can do so by modifying the daily sales and lead time.